Please add some products from our shop, so we can generate a quote for you.

SOUTH AUSSIE MADE AND OWNED

Poly Rainwater Tanks Adelaide

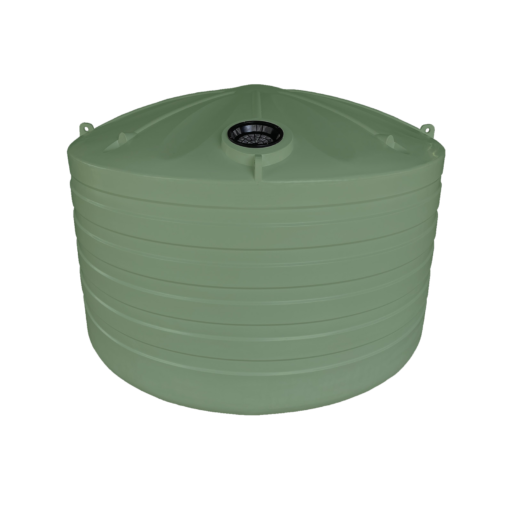

APR Tanks manufactures a range of slimline and round polyethylene rainwater tanks locally at our factory in Edinburgh. Sizes range from 1,000 litres to 20,000 litres and come in a range of Colourbond® matching colours to suit your home or property.

Our tanks are manufactured to Australian Standard AS/NZS 4766 for poly tanks and Australian Standard AS/NZS 4020 for drinking water and come with a 10 Year Manufacturer's Warranty. If you're looking for maximum capacity and the best value for money, then a round tank is your best option. If space is limited our slimline range of tanks is an ideal choice.

Poly tanks are polyethylene storage containers designed for diverse applications, including water storage, chemical storage, and agricultural use. Manufactured via rotational moulding, these tanks are known for their durability and chemical resistance. They come in a variety of shapes, colours, and sizes, with customisation options available to meet specific requirements. Poly tanks are highly resistant to UV rays and temperature fluctuations, making them suitable for outdoor environments. Their advantages over steel tanks include lighter weight, corrosion resistance, and lower installation costs, making them a preferred choice in many industries.

What is a poly tank?

A polyethylene or poly tank is a storage container made from high-density plastic designed to hold liquids or chemicals. These tanks are widely used for water storage, serving various household uses, agricultural applications, and industrial applications.

Poly tanks are known for their durability and versatility, accommodating a range of capacities to meet different needs. Poly water tanks can be equipped with custom fittings to guarantee they meet specific requirements. These quality products are preferred for their resilience to environmental factors and ease of maintenance.

How are poly tanks manufactured?

Poly tanks are manufactured by the process of rotational molding. In this method, polyethylene powder is precisely placed into a mould, which is then heated as it rotates to ensure a uniform coating and consistent wall thickness. As the material melts, the mould is gradually cooled to solidify the tank's structure.

Upon completion, the mould is opened to release the robust tank, which is then fitted with the necessary attachments. Each tank undergoes stringent quality checks to meet defined performance standards, resulting in a product that is durable and chemically resistant, suitable for various storage applications.

What materials comprise a poly tank?

Polyethylene storage tanks are crafted from high-grade plastic polyethylene. Available in a spectrum of grades such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE), these tanks are engineered to meet the Australian standard requirements for strength and flexibility.

While polyethylene remains the primary choice, alternative materials are occasionally employed to tailor solutions for unique applications. The tanks also come in a range of colours, designed to suit a wide range of tastes and functional needs.

What are the types of poly tanks?

The primary types of poly tanks include vertical poly tanks, horizontal poly tanks, cone bottom poly tanks, slimline poly tanks, underground poly tanks, stackable poly tanks, open top poly tanks, and IBC poly tanks. Recognising these variations aids in choosing the most appropriate tank for your storage requirements.

1. What is a vertical poly tank?

A vertical poly tank is a type of polyethylene storage container designed for upright installation and is commonly used for storing liquids such as water, chemicals, and fertilisers. These polyethylene plastic tanks offer a range of capacities suitable for farm storage, industrial tanks, and various water usages, including irrigation systems and drinking water tanks. Known for their excellent service life and competitive prices, vertical poly tanks serve a broad range of household uses.

2. What is a horizontal poly tank?

Horizontal poly tanks are designed for horizontal installation and are commonly used for transportation and storage applications. Their design facilitates ease of transport, making them ideal for agricultural and commercial applications. They are often equipped with a self-cleaning system to maintain hygiene and efficiency. In manufacturing tanks, horizontal poly tanks are preferred for their stability and ability to fit into tight spaces.

3. What is a cone bottom poly tank?

Cone bottom poly tanks provide unique advantages for particular applications. Often used in commercial property storage, their conical shape ensures maximum strength, enables efficient drainage, and facilitates easy cleaning.

The three key features of cone bottom poly tanks include:

- Self-cleaning system: The conical shape ensures complete drainage, reduces residue buildup, and provides maximum strength.

- Versatile tank fittings: These tanks can be customised with various fittings to suit different needs and offer maximum durability.

- Tank for transport: The conical design minimises liquid sloshing and improves stability during transport, ensuring maximum safety.

4. What is a slimline poly tank?

Slimline poly tanks are designed to maximise water storage in areas with limited space. These slim poly water tanks are ideal for households that require a space-saving solution. Their compact underdeck tank design allows them to fit into narrow or confined spaces, making them an ideal size tank for urban environments. Despite their slim profile, these poly water tanks can store a significant volume of harvestable water for various applications, from garden irrigation to household water supply.

5. What is an underground poly tank?

Underground poly tanks are designed to be buried beneath the surface, providing a discreet and space-efficient water storage solution. These ground tanks are ideal for various applications, particularly in areas with limited space or stringent aesthetic requirements. These ground water tanks are engineered to meet the demands of both residential and commercial properties, offering a practical solution for garden water storage and other needs.

Underground poly tanks are suitable for:

- Emergency water supply: Secures a steady reserve of water during emergencies.

- Irrigation to water: Provides water for farming products and vegetable gardens.

- Australian conditions: Constructed to withstand harsh environmental conditions.

6. What is a stackable poly tank?

Stackable poly tanks are designed to be easily stacked for efficient storage and transportation, making them an ideal choice for a variety of applications. These poly tanks come in a variety of models, including poly rain water tanks and poly potable water tanks. Manufacturers offer them in different design shapes, such as round poly and rectangular configurations, to suit specific needs.

7. What is an open top poly tank?

An open top poly tank is a versatile plastic tank crafted from polyethylene, featuring an open top for easy access. This design adheres to tank standards and is particularly useful in sectors that require frequent filling, mixing, or sampling, such as chemical manufacturing, food and beverage processing, and water treatment.

The open top facilitates efficient mixing, enhancing operational efficiency. These tanks are available in various sizes and can be equipped with custom tank fittings. Optional lids or covers are also available to protect the contents from debris or contamination.

8. What is an IBC poly tank?

An IBC (Intermediate Bulk Container) poly tank is a reusable industrial-grade container designed for the efficient transport and storage of bulk liquids and granulated substances, including chemicals, food ingredients, solvents, and pharmaceuticals.

Crafted from high-density polyethylene (HDPE) and reinforced with a protective galvanised steel cage, these tanks boast enhanced durability and are engineered for optimal stackability. Standardised in size and capacity, IBC poly tanks generally hold between 275 and 330 gallons, making them an indispensable solution for industries seeking reliable and cost-effective storage and transportation options.

What sizes are available for poly tanks?

Poly tanks are available in a wide range of sizes to suit various storage needs. Common tank sizes can range from tiny, 10-gallon tanks to the largest poly tank choices exceeding 10,000 gallons. These tanks often come in a round tank design, with diameter tanks providing stability and capacity. Squat profiletanks are also available for limited height spaces. Wholesale poly tank solutions offer a variety of options to meet specific requirements, and expert manufacturing guarantees quality.

What colours can poly tanks have?

Poly tanks are available in a broad colour range, including colour names such as black, green, blue, white, and tan. The choice of colour impacts the tank's functionality. Dark colours such as black and green reduce algae growth by limiting sunlight exposure. This selection prevents incorrect colour impressions that could compromise the tank's effectiveness. During the production of polyethylene storage tanks, manufacturers tackle colour fading to maintain durability and visual appeal, even with environmental exposure.

How much does a poly tank weigh?

The weight of a polyethylene tank varies significantly based on its size, thickness, and specific design. Small poly tanks may weigh as little as 20 pounds (approximately 9 kilogrammes), while larger models can reach several hundred pounds.

For example, a typical 500-gallon poly tank weighs about 95 pounds when empty, although this can differ depending on the manufacturer and model specifics. These tanks are commonly used as rainwater tanks or litre water tanks, providing an ideal tank solution for supplying water safely, ensuring that water tanks are safe for consumption, and various other applications.

What typical uses do poly tanks have?

Poly tanks are extensively employed in Australian agriculture for water storage, chemical storage, and irrigation systems. Their double strength construction makes them ideal for handling large volumes of liquids. Poly tanks facilitate mains water supply and volume harvestable, enhancing the capacity for farm storage. Additionally, they supply water safely, ensuring water tanks are safe for various Australian household uses.

What industries gain from using poly tanks?

Industries such as construction and chemical processing benefit greatly from using poly tanks. In construction, these tanks are used for water storage and mixing materials, while in chemical processing, they store various chemicals with necessary safety measures. Ensuring proper handling and storage is vital to prevent leaks and contamination.

Why are poly tanks favoured in agriculture?

In agriculture, poly tanks are particularly favoured for their durability, versatility, and cost-effectiveness in storing and transporting water, fertilisers, and other necessary liquids. These tanks play an essential role in farm management by efficiently managing the natural water supply, especially from rain. Common uses include:

- Water Storage: Poly tanks, including the largest water tank models, store rainwater and grey water for irrigation and sprinkler systems.

- Chemical Storage: They are ideal for holding fertilisers and pesticides, guaranteeing safe and effective farm operations.

- Fuel and Waste Management: Poly tanks serve as fuel tanks and septic tanks, supported by an experienced delivery team to ensure proper installation.

What are the construction applications for poly tanks?

In construction applications, poly tanks offer several advantages over traditional materials, such as:

- Sewage Treatment:Poly tanks are ideal for storing waste water and sewage, often integrated with pumps and advanced inlet height systems for efficient management.

- Water Storage: They provide reliable water storage solutions essential for day-to-day life on construction sites, featuring tank self-cleaning systems.

- Durability:Poly tanks come with an impressive warranty, ensuring long-term use without frequent replacements.

What safety measures are needed for storing chemicals in poly tanks?

Storing chemicals in poly tanks requires meticulous safety measures to ensure proper handling and prevent accidents or environmental harm. These safety measures include:

- Chemical Compatibility: Verify the polyethylene material's compatibility with the chemical to avoid reactions that could compromise the tank. This is particularly important when storing animal-care products.

- Venting: Equip tanks with venting systems to control gases or fumes from volatile chemicals.

- Secondary Containment: Implement secondary containment systems like bunds or double-walled tanks for spill and leak management.

- Labelling: Label tanks clearly with contents, hazard symbols, and handling instructions.

- Positioning: Position tanks in areas that are accessible yet isolated from high-traffic or environmentally sensitive zones.

- Regular Inspections: Conduct regular inspections to detect leaks, corrosion, or damage, focusing on connections and fittings. This includes the testing of products stored.

- Temperature Control: Maintain specific temperature conditions to prevent adverse chemical reactions.

- Emergency Plan: Develop and update emergency response plans covering procedures for managing spills, leaks, and exposure risks.

- Model of Tank: Choose the appropriate model of tank that meets the specific requirements and comes with a 10-year warranty for added assurance.

Why opt for poly tanks for water storage?

Opting for poly tanks for water storage presents a safe, durable solution, as these water tanks are customisable and robustly durable. Their capacity is crucial in meeting specific storage needs, and they are available in a variety of shapes to accommodate different spaces and functions.

Are poly tanks safe for drinking water?

Yes, poly tanks are safe for drinking water. They are crafted from food-grade polyethylene that does not leach harmful substances, ensuring the water stored inside remains uncontaminated and safe for consumption. This makes them an excellent choice for the average household, as these water tanks meet health and safety standards.

How does the capacity of a tank affect its selection?

Evaluating the capacity of a tank is vital in determining its suitability for various water storage needs. Poly tanks offer a wide range of capacities, making them ideal for different functional uses. Selection often depends on the household's water consumption and the available installation space.

For instance, larger tanks round in shape may be chosen for extensive irrigation needs, while smaller units fit residential purposes. Inlet height and the angle of tank placement are also essential factors, especially for delivery drivers managing water distribution.

How durable are poly tanks?

Poly tanks are highly durable and offer substantial resistance to UV rays, which prevents degradation from prolonged sun exposure. They can withstand extreme temperatures, ensuring reliable performance in both hot and cold climates. These attributes make poly tanks a dependable choice for long-term water storage.

How resistant to UV are poly tanks?

Poly tanks are highly resistant to UV rays. They are typically manufactured using UV-stabilised polyethylene, which helps prevent the material from breaking down or degrading when exposed to sunlight over extended periods. This UV resistance ensures that the tanks maintain their structural integrity and functionality for many years, making them suitable for outdoor environments.

How do poly tanks cope with extreme temperatures?

Extreme temperatures are a common concern for water storage solutions, but poly tanks are engineered to handle both high and low temperature variations effectively. Made from high-quality polyethylene, these tanks resist cracking and warping in freezing conditions and maintain their structural integrity in extreme heat. This durability guarantees reliable water storage, making poly tanks a practical choice for diverse climates.

Can poly tanks be customised?

Yes, poly tanks can be customised to suit specific needs, including size, shape, capacity, and color. Options like a ball valve, brass outlet, and various inlet configurations, such as an inlet strainer, are available. Tanks can also be made with a corrugated wall profile for added strength and a normal shape, or in customised forms. Additional customisations can include colour matching with a colour sample and add-ons like the delivery of pumps tailored to the tank’s use.

Custom features might entail an inlet height freight consideration for logistics. These tanks often come with a 25-year warranty, ensuring long-term service without ongoing expenses.

What fittings are compatible with poly tanks?

Several types of fittings, including brass, stainless steel, and PVC, are compatible with poly tanks. These fittings provide secure and reliable connections for various applications. Key options include:

- Brass fittings: Known for their durability and corrosion resistance.

- Stainless steel fittings: Ideal for high-pressure systems and longevity.

- PVC fittings: Cost-effective and easy to install.

How do you select the appropriate poly tank?

Selecting the appropriate poly tank involves evaluating factors such as capacity, material quality, and intended use, especially for an additional household. Poly tanks have advantages over steel tanks, including resistance to corrosion, lighter weight, and ease of installation.

Poly tank vs Steel tank: What is the difference?

Poly tanks are crafted from corrosion-resistant polyethylene, making them lighter and more adaptable in shape, which simplifies and reduces the cost of installation compared to steel tanks. Steel tanks, while possibly more durable, are heavier and susceptible to rust, necessitating frequent maintenance and protective coatings.

Poly tanks excel in chemical resistance and initial cost-effectiveness, whereas steel tanks are suited for harsher conditions with adequate upkeep. The selection between the two depends on specific storage requirements and environmental factors.

grey tankstanks polypoly waterpoly toteshome tanksaquaculturetanks roundround watertanks waterround tankswater pumpswater usagepoly septicseptic tanksdiesel tanksstorage tankpoly cisterntank standardconcrete tankdiameter tankcleaner watertank deliverypoly oil tanktank selectortank containerpro poly tanksfire poly tankblue poly tanktank deliveredtanks slimlineslimline tankspoly water tankdelivery driverlitre water tankpoly water tankspoly dosing tankdiesel tank polypoly nurse tankspoly truck tankspoly cattle tankrapid poly tankspoly tank squarepoly sewer tankswater tank pumpsfertiliser tanksplastic ag tanksrain water tankspoly septic tankground water tankpolyethylene tankspoly transfer tankpoly tanks midlandpoly cartage tankspoly storage tankspolytop water tankpoly cistern tanksplastic tank smallplastic farm tankspolyethylene waterplastic bulk tanksplastic stock tankplastic container tankpoly plastic water tanks

What others are saying about us

C

Carly & Stuart

Adelaide Hills, SA

We lost our rainwater tanks in the Cudlee Creek bush fires and needed quality replacement tanks delivered quickly. We chose APR as we have previously used their products and were so impressed with their durability and reliable service.

P

Paul

Kapunda, SA

I am very happy with the tank delivery. Your driver was professional and friendly, and helped us get the tank into the right spot. I would have no hesitation in recommending APR Tanks.

B

Bob

Fleurieu Peninsula, SA

Thank you for the tank, it looks great and is now plumbed in and fully functional. Your driver was excellent. We worked together as a team to position the tank and he was very accommodating given the challenging weather conditions.

P

Poey Steve

Edinburgh SA

Their services are great ,everything about them was extremely satisfying ,couldn't ask for more ,was very

impressed with the tanks very well made and easy to setup A++++ highly recommended

impressed with the tanks very well made and easy to setup A++++ highly recommended